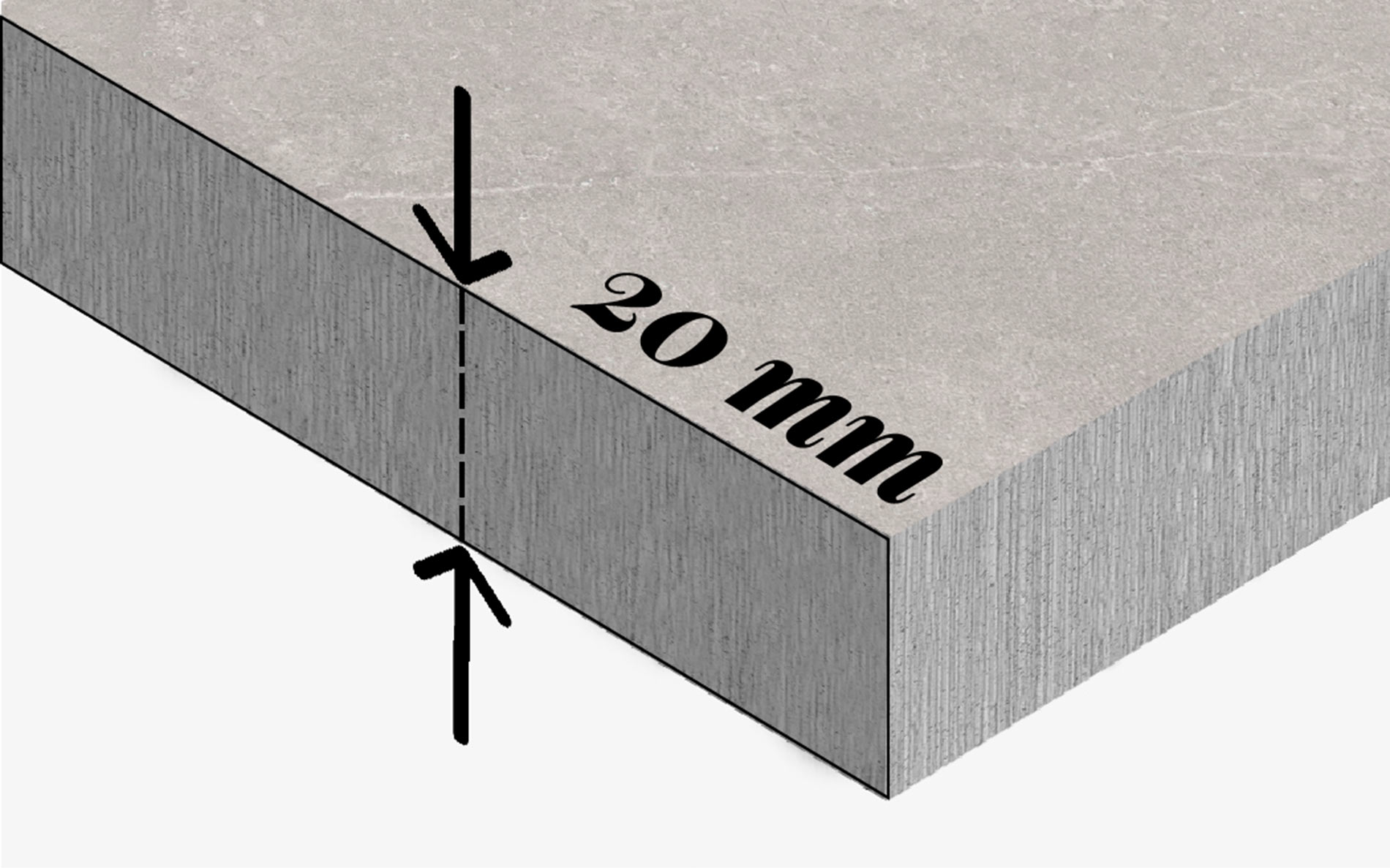

Ultimate Guide to Cutting 20mm Thick Tiles with a Manual Tile Cutter

time2024/10/25

- This article discusses techniques and tools for cutting 20mm thick tiles, focusing on the TILER 8102G-3Y manual cutter and strategies for precision and durability.

In modern construction and renovation projects, 20mm thick tiles are popular for their durability and aesthetic appeal. However, cutting tiles of this thickness presents challenges, especially when the material is porcelain or stone. This article will explore the techniques for cutting 20mm thick tiles using a manual tile cutter.

Challenges of Cutting 20mm Thick Tiles and Solutions

The challenges of cutting 20mm thick tiles primarily include the following:

1. Hardness and Brittleness

20mm thick tiles are typically harder and more brittle than thinner tiles, making them more prone to breakage or cracking during cutting.

Solution: Use a high-quality cutter designed for thick tiles, such as the TILER 8102G-3Y. This cutter is equipped with stronger cutting wheels and a robust structure to handle the hardness of thick tiles.

2. Cutting Force Requirements

Thicker tiles require greater cutting force, which can overload the cutter or blade, affecting cutting performance and the lifespan of the equipment.

Solution: Choose a cutter with sufficient load capacity, like the TILER 8102G-3Y, which has a separation power of 1200kgs, making it suitable for cutting thick tiles.

3. Blade Wear

The cutting process for thick tiles results in faster blade wear, necessitating more frequent sharpening and replacement.

Solution: Use durable blade materials, such as carbide or specially coated blades, and perform regular sharpening and replacement to maintain cutting performance.

4. Cutting Precision

Cutting thick tiles requires higher precision, as even minor errors can lead to uneven installation.

Solution: Utilize high-precision cutting machines equipped with laser guides or infrared positioning systems to ensure accurate cutting lines.

5. Visibility of Cutting Path

Ensuring the cutting path is visible helps avoid cutting misalignment or errors.

Solution: Use a cutter with a magnetic locking foot, like the TILER 8102G-3Y, to maintain stability and visibility during the cutting process.

By addressing these challenges with appropriate methods, you can ensure a smooth cutting process and high-quality final installation.

How to Ensure Cutting Precision of 1mm or Less for 20mm Tiles?

To achieve a cutting precision of 1mm or less for 20mm thick tiles, precise cutting tools and meticulous operational techniques are essential. Here are several key steps:

1. Use a High-Precision Cutter

Choose a professional manual tile cutter like the TILER 8102G-3Y, designed for accurate cutting and typically equipped with precise laser guides or infrared positioning systems to ensure cutting line accuracy.

2. Blade Selection

Use high-quality carbide blades that offer high hardness and wear resistance, suitable for cutting hard materials, ensuring optimal cutting results.

3. Adjust Cutting Depth and Angle

Adjust the cutting depth and angle according to the thickness of the tile and the desired cutting angle. Ensure that the cutting depth is moderate to avoid damaging the blade or the tile. Utilize the side stop feature for repeated cuts and precise angle adjustments.

4. Control Pushing Speed

Maintain a steady and appropriate pushing speed during cutting, avoiding excessive force. Especially as you near the end of the cut, slow down to ensure cutting quality.

5. Post-Cutting Inspection

Immediately check the cut surface after cutting to ensure there are no cracks or defects, addressing any issues promptly.

6. Maintenance and Cleaning

Regularly clean the cutter and blade to ensure all parts of the cutter operate smoothly, which helps maintain cutting precision.

7. Operator Skills

The operator should have a certain level of experience and skill, familiar with the operation and maintenance of the cutter to enhance cutting efficiency and quality.

Conclusion

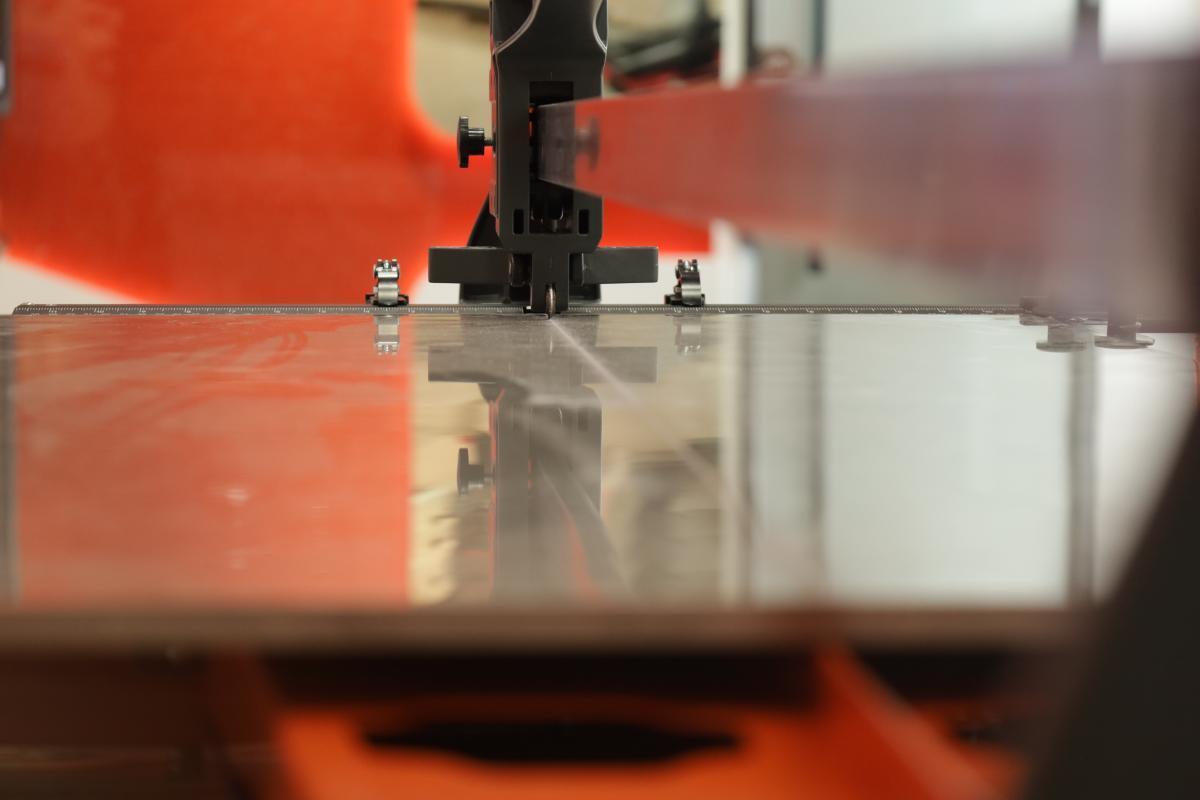

The TILER 8102G-3Y manual tile cutter not only has a high load capacity (separation power of 1200kgs) but can also handle tiles up to 20mm thick, making it suitable for high-volume tiling projects. Its durability comes from a steel base and reinforced alloy steel guide rails, with a cutting wheel lifespan of up to 2000 meters. Additionally, the cutter features a pair of extension arms that support a maximum width expansion of 930mm, making it ideal for cutting large tiles.

By mastering the above techniques and using high-performance tools, you can effectively cut 20mm thick tiles and ensure the smooth progression of your tiling projects.

Here is the 8102G-3Y tile cutter :