Common Faults and Solutions of Electric Tile Cutting Machines

time2023/12/05

- Electric tile cutters have become an indispensable tool in the field of decoration. Read on to learn more about common faults related to electric tile cutters to help you make better use of them.

Electric tile cutters have become an indispensable tool in the construction and home improvement fields. Their ability to cut tiles accurately and quickly makes them a favorite among professionals and DIY enthusiasts alike. However, even the most reliable machines can face problems over time.

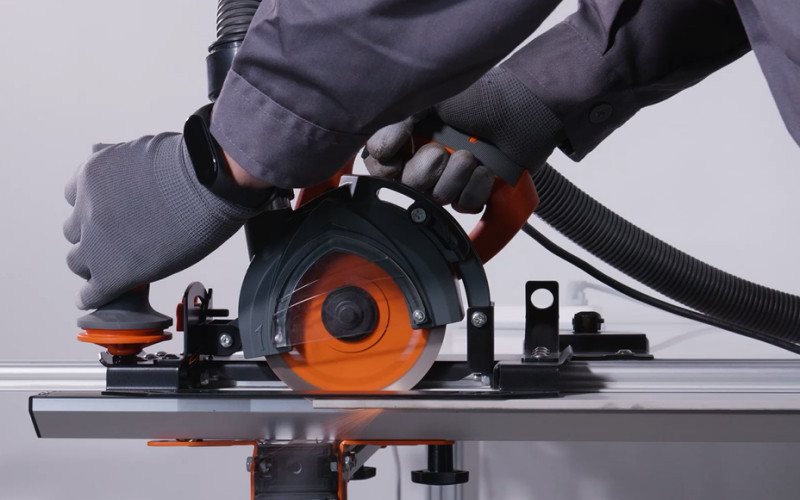

Fault 1: Blade Problem

The blade is the heart of any tile cutter, and problems with it can result in poor cutting results or even machine failure. Check the blade regularly for wear and make sure it is sharp and free of chips. Consider replacing blades that show signs of damage.

A dull or damaged blade can cause jagged edges on the tile, making it unusable for your project. Additionally, a damaged blade puts additional stress on the motor, which can lead to more serious problems.

To maintain optimal blade performance, follow the manufacturer's recommendations for sharpening or replacing blades. Always use the type of blade appropriate for the material you are cutting to prevent unnecessary wear.

Fault 2: Power Supply Problem

Power supply issues are a common culprit of machine failure. Check power supplies, cables, and connections regularly. If the machine does not receive enough power, it can result in inefficient cutting or complete failure.

Make sure the electrical outlet is working properly and the power cord has no loose connections. If you use an extension cord, make sure it can meet the power requirements of the machine.

In some cases, power fluctuations or surges can damage machines over time. Consider using a surge protector to protect your electric tile cutter from electrical problems.

Fault 3: Overheating

Continuous operation may cause overheating, affecting the performance and life of the machine. Allow the machine to cool down between extended uses, and consider investing in a model with a built-in cooling mechanism.

Overheating can be caused by a variety of factors, including cooling system failure or insufficient ventilation. Check machine vents for blockages and clean them regularly.

If your machine doesn't have a built-in cooling system, take breaks during extended use to prevent overheating. Additionally, operating the machine at lower speeds for complex cuts helps reduce heat build-up.

Fault 4: Water Pump Failure

The water pump in an electric tile cutter is essential for cooling the blades and reducing dust. Check and clean your water pump regularly to ensure optimal function. If the pump shows signs of wear, consider replacing the pump.

Water pump failure can cause overheating and reduce cutting efficiency. Check the pump for any blockage or damage and clean it thoroughly. If the pump still doesn't work after cleaning, replace it immediately to avoid further complications.

Fault 5: Inaccurate Cutting

Inaccurate cuts can be frustrating and wasteful. Make sure the machine is on a stable surface and check the cutting guides carefully. A dull or misaligned blade can also lead to inaccurate cuts.

Before starting a cutting operation, make sure the machine is securely positioned and the cutting guides are properly aligned. If the guide is adjustable, take the time to set it up exactly for your specific project.

Check the sharpness of the blade regularly and replace it if necessary. Worn bearings or misaligned components can also cause inaccuracies. Perform routine maintenance checks to resolve these issues promptly.

Fault 6: Motor Problem

The motor powers the entire cutting process and any problems could be detrimental. Keep the motor clean and well-lubricated. Unusual sounds or vibrations may indicate a movement problem that requires immediate attention.

Check the motor regularly for any visible signs of damage or wear. Lubricate moving parts according to the manufacturer's recommendations to reduce friction and prevent premature motor failure.

Unusual sounds, such as grinding or squealing, may indicate worn or misaligned bearings. If you notice any such noise, shut down the machine immediately and correct the problem before resuming operation.

Fault 7: Security Issues

Safety should always be your top priority when operating an electric tile cutter. Regularly check safety devices such as blade guards and emergency stops. Invest in personal protective equipment to minimize risk.

Make sure all safety features are functioning properly before using the machine. If any safety part is damaged or malfunctions, do not use the machine until the problem is corrected.

Wear appropriate personal protective equipment, including safety glasses and ear protection, to protect against potential hazards. Additionally, follow all safety guidelines provided by the manufacturer in the machine owner's manual.

Fault 8: Belt Problem

Belts play a vital role in transmitting power within the machine. Regularly check the belt for wear and proper tension. A loose or damaged belt can cause inefficiency and increase wear on other components.

Check the condition of the belt during routine maintenance inspections. If you notice any signs of wear, stretch, or damage, replace the belt immediately to prevent sudden failure during operation.

Make sure the belt is properly tensioned according to the manufacturer's specifications. Belts that are too tight or too loose can affect the overall performance of the machine and cause premature wear on the motor and other components.

In Conclusion

In summary, addressing common faults with electric tile cutters is crucial to maintaining efficiency and extending the life of your machine. Regular inspections, proper maintenance, and prompt problem resolution help create a seamless cutting experience. By following the outlined solutions, users can ensure their machines are running at peak performance, delivering precise cuts for a variety of tile projects. If you want to know more about electric tile-cutting machines, please contact us.

TILER is a professional custom tile tools manufacturer. We advocate the spirit of craftsmanship and are always committed to creating perfect, efficient, innovative, and professional tile-cutting and laying tools. Our six product categories cover all the tools you need for tile decoration, including large panel systems, tile cutters, tile handling and laying tools, tile leveling tools, grouting and cleaning tools, and other tile tools.

Frequently Asked Questions

How often should I replace my cutting blade?

It depends on usage, but in general, consider replacing your blades when they show signs of wear or inefficiency.

What safety measures should be taken when using a tile cutter?

Always wear protective gear, follow the manufacturer's guidelines, and make sure the machine is on a stable surface.

Can I use any type of water in the machine's pump?

Use clean water and, if recommended, add appropriate additives to prevent bacterial growth.

How to solve power problems?

Check the power supply, cables, and connections for any faults. If the problem persists, consider consulting a professional.

TILER Large Format Slab Cutter 2 in 1 Kit DE-125 suitable for cutting large format slab with a thickness of 4 to 25mm.

TILER DE-125M is a powerful tool designed for cutting and shaping marble and other types of stone with precision and ease.